C - Fire Ratings

One of the most critical issues and code requirements for architects is ensuring that building design addresses fire safety issues. The building codes require fire resistance ratings for floor assemblies. A fire-resistance rating refers to the period (1 hour, 1 ½ hour 2 hours, and 3 hours) an assembly can contain a fire and perform its intended structural function. These ratings are determined by subjecting an assembly to a standard fire exposure as defined in ASTM E119.

Through testing and evaluation by Underwriters, Laboratory Vescom has multiple approved Underwriter Laboratory approved fire-rated assemblies including sheetrock ceilings, acoustical ceiling panels, and spray-on fireproofing.

Ceiling Assemblies with Sheetrock (Gypsum Board Membrane) Ceilings

Vescom has accomplished a fire-rated assembly that services all the fire code requirements and at the same time meets all the mechanical

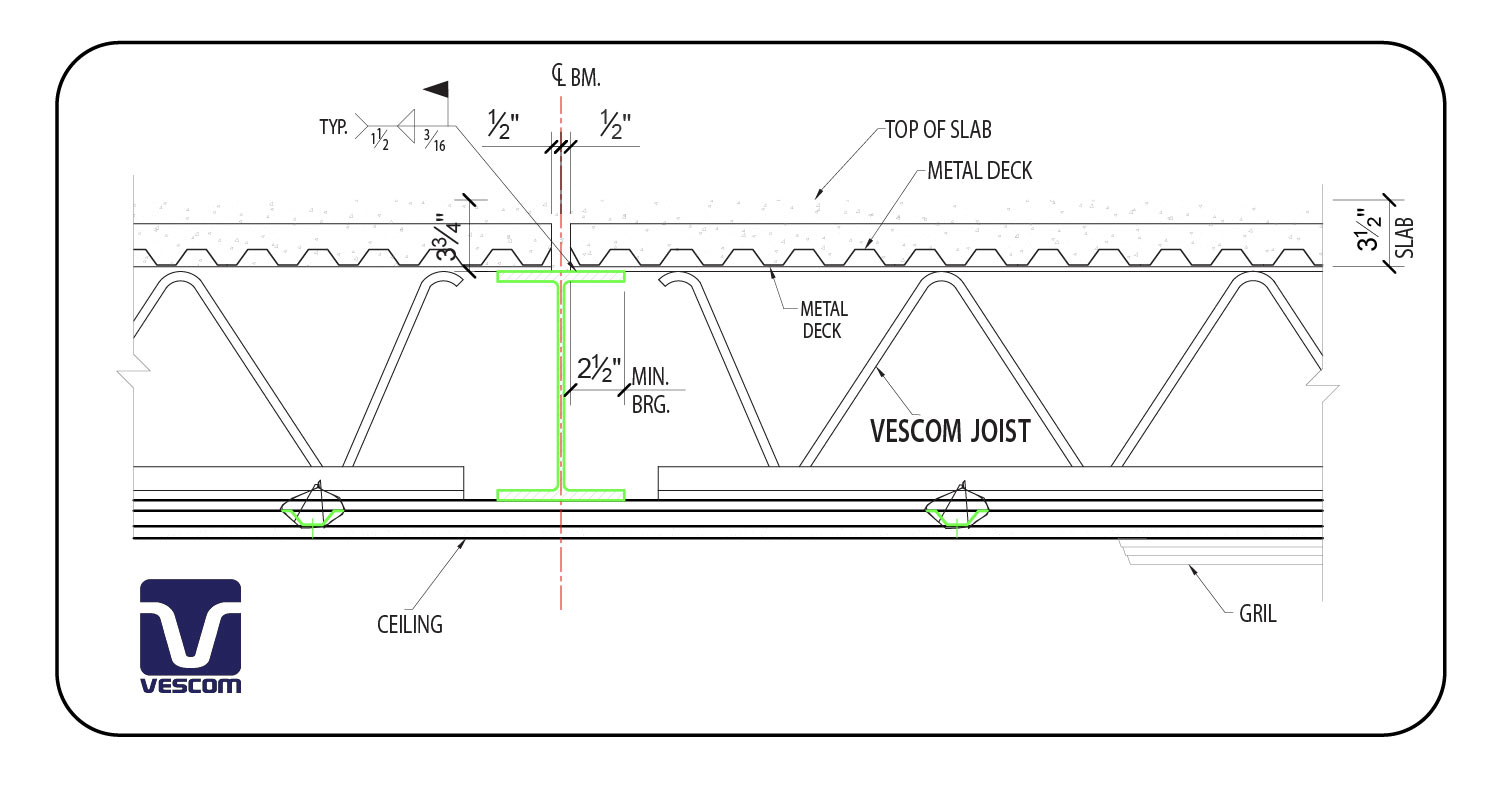

Vescom’s premier UL Fire Rating for residential buildings is BXUV.G531. These ratings cover 95% of residential work. By attaching the ceiling to the joist bottom chord the cost of the ceiling is reduced by 2/3rd. The sheetrock ceiling can be level with no soffits since the circulating mechanical distribution goes within the plenum of the joists. There are multiple ratings with sheetrock ceilings. They are listed in the G500s. BXUV.G531 is the most inclusive and is summarized in detail.

Acoustical Ceiling Lay in Panels

Acoustical ceiling assembly areas are covered under UL Ratings such as in commercial or institutional applications are in the G200s. They include the handing of recessed lighting and large duct ceiling penetrations.

Spray on Fireproofing

These ratings involve multiple types of spray fireproofing and multiple manufacturers. The applications are normally on the commercial and institutional buildings where occupancy or use will change periodically and required renovation periodically. Vescom has built multiple speculative office buildings where spray fireproofing assemblies were the preferred choice. The spaying of open web joist is accomplished predominately by applying nylon mesh to the webs first with an adhesive, spraying one side concentrating on the web, waiting to dry, and then spraying the other side.

Commentary on BXUV>G531

This table below lists fire-resistant assemblies using Vescom joist systems, as well as the related evaluation reports. The actual UL Ratings are embedded for your reference.

BXUV.G531 Summary and Commentary

The most prolific UL Rating which we use is BXUV.G531. It is for residential, senior living, and hotel-type occupancy. Over the years it has been expanded to meet the needs of the residential marketplace with the ever-increasing demand for different mechanical and architectural innovations. As with all the UL Vescom ratings “if you don’t see it”, that does not mean we cannot work with UL to extrapolate from previous tests and experience the assemblies need for a specific project.

| Requirements | Commentary |

|---|---|

| RequirementsThe concrete requirement is 3500 PSI normal weight concrete. It is 2 3/16” of concrete on a 1 5/16 metal decking for a total of 3 ½” | CommentaryMany projects over the years have been built with thicker or thinner slabs. Some used lightweight concrete. Many engineers want to use 4000 PSI concrete. |

| RequirementsOne layer of ½” or 5/8” Type C sheetrock is required for the ceiling | CommentaryTo attach the one layer of sheetrock, 7/8” 25-gauge hat channels are attached to the bottom chord of the joist 2’-0” on center. |

| Requirements8” joists and deeper can be used with this rating while allowing for unprotected openings as specified in the rating. | Commentary6” joists are allowed but do not qualify for the liberal mechanical openings allowed with deeper joists. |

| RequirementsThe size of the welded wire mesh is 6 X 6 W2.0/W2.0 or heavier. It is determined by the structural requirement of the span and the load. | CommentaryThe normal parameter of the residential slab construction, which is a 40-pound live load, spans 52” between joists and requires the W2.0/w2.0 wwm. When the parameters change heavier mesh may be required. When it is in just one part of the project, we double up the mesh and it is sufficient |

| RequirementsThe usual spans between the joist are 52”. This is modified in multiple cases due to plumbing, mechanical, electrical, or architectural, conflicts. | CommentaryThe rating allows 6’-0” spacing under the limitation that three (3) adjacent spans will not be more than 14 feet. The need for the 6-foot spacing usually occurs with back-to-back bathrooms or the need for a mechanical unit between joists. |

| RequirementsThe decking used for this rating is a 1 5/16” galvanized 24-gauge decking. | CommentaryAnother size decking is sometimes used for a special requirement on the project. Since the concrete acts as a heat sink in the case of a fire, the volume of concrete per square foot must equal or exceed the typical condition. |

| RequirementsUnprotected duct opening is allowed if they are a maximum of 20 square inches where they are not within 12” of a joist. One unprotected opening is allowed for every 100 square feet of ceiling area. | CommentaryIf an apartment is 1200 square feet, 12 unprotected openings are allowed. These 100 sq. ft. areas are not 10’ X 10’ areas but can be interpreted to mean 12 openings where these openings are not clustered or concentrated in one area of the apartment. |

| RequirementsEquivalent to unprotected duct opening are “plenum box outlets” which are larger than 20 square inches, but their construction allows them to be unprotected. | CommentaryVarious ceiling penetrations are allowed which are equivalents to the 20 square inch opening including 6” and 8” rounds, 10” X8” rectangular, 10” X10”, 14” X14” and openings for lights, exhaust duct, etc. Each opening construction is spelled out in the UL Rating. |

| RequirementsVarious Flexible Air ducts with equivalent ceiling penetrations are allowed. | CommentaryThis allows flexible exhaust air ducts for bathrooms and kitchens to travel though the joists to the exterior wall. Venting through the exterior wall eliminates the vertical exhaust duct to the roof traditionally used. It also eliminates the floor-to-floor sound transfer which is so disturbing to residence. |

| RequirementsHanging the ceiling is also allowed. | CommentaryVarious hung ceilings assemblies are allowed. This gives contractors flexibility where lower ceilings are required, or there are other reasons to hang the ceiling as opposed to attaching it. |

This table below lists fire-resistant assemblies using Vescom joist systems, as well as the related evaluation reports. The actual UL Ratings are embedded for your reference.